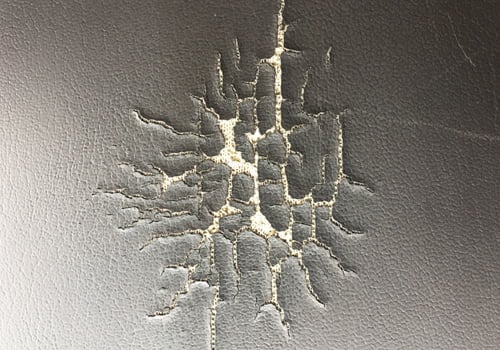

As vinyl desiccates (dries out), it develops cracks that often have sharp edges that curl upward. These must be carefully shaved away or melted and compressed. Even the most skillful repairs often result in a slightly elevated mound. Repairs on high-stress areas (like the side of a driver seat or the center console in a car) cannot be expected to perform any better than the original and may re-crack if exposed to the same stressors.

While you can use a low-temperature putty like our Soft Filler, the superior method for repairing cracks in vinyl is to use a higher-temperature heat-cure putty. This requires a heat gun and graining pads as per these instructions. Scroll below for a video demonstration.

- Subpatch and glue any holes.

- Holding a clean, new razor blade almost parallel to the surface, carefully shave away any sharp, curling edges that stand high above the surface.

- Those too low-profile or risky to shave can be gently melted with the heat gun ~550°F at a distance of 2″-6″ for 5 to 15 seconds (we’ve even ‘nuked’ some heavier duty vinyls with 1000°F and a reducer nozzle, but be cautious). The vinyl will begin to get more glossy.

- Remove the heat gun, and immediately apply the grain pad. Use a small board or block to apply even pressure and avoid dents in the upholstery. Hold for 10 to 15 seconds.

- Repeat as necessary. The vinyl needs to be room temperature and as level as possible before filler is applied.

- Clean the vinyl with denatured or rubbing alcohol.

- Using a palette knife or needle tool, apply a thin coat of heat-cure filler. Level and remove excess with a plastic spreader.

- Use the heat gun ~550°F at a distance of 8-10″ from the repair and warm until the filler begins to change from a glossy white cream to a more translucent, frosted appearance. If it gets very hot, it will become glossy again and will better receive the grain, but be careful not to melt the surrounding area.

- Immediately apply the grain pad and wooden block using gentle, even pressure. Hold for a 5 to 10 seconds. This will emboss the filler as it cools. The pressure imparted will also help level any ridges or high spots.

- Allow the surface to return to room temperature before continuing. Some pros invest in a chill block, but water and a few minutes will do the trick.

- Repeat steps 7-10 until the surface feels even.

- If necessary, apply a final thin coat of heat-cure filler and texturize with a gloved hand to blend any lines or inconsistencies in texture. Heat and emboss with grain pad once more.

- You can also use a spray grain like SEM Chip Guard to further blend texture.

- Apply Rub ‘n Restore® color and Clear Prep+Finish™ if desired.

- If the repair needs, re-working, use our Flite™ cleaner or rubbing alcohol to remove the color before applying more heat-cure filler.

This video demonstrates the process, albeit on real leather, not vinyl:

- 0:21 – Air dry vs. heat cure leather repair putties

- 1:07 – Use a solvent to clean

- 2:02 – Apply heat cure putty

- 2:48 – Caution: heat guns can shrink leather

- 3:15 – Emboss the cured filler with a grain pad

- 4:13 – Once cool, repeat

- 5:38 – Level any wrinkles and ridges

- 9:45 – Final texturizing

- 12:00 – Info about spray grains

For years we used SEM’s heat-cure compound, but it is no longer available. Your best bet is Refinish Coatings’ standard or soft flex compound.

If you plan to make this a hobby or vocation, invest in a good set of graining pads for embossing. You can also buy a graining kit comprised of a compound and a catalyst to make your own. Buy only as much as you need, as the compound and catalyst spoil within a few months. Or commit to making a variety of graining pads, as they will last decades.

I need to Fix a Leather or Vinyl car (2013 Ford EDGE) center-arm rest. its slightly cracked and now opening up – its about 3-4 inches long. Where can I buy a repair kit?

Your Info is appreciated! Much!

As per this article, the best solution is to invest in a heat gun and heat-cure filler, possibly a graining kit. Short of that, best you can do is subpatch and use our air-dry filler.

Can I send you a pic of needed repair on a car seat…get info on what we need to fix it?

Minor nicks in the leather can be repaired with tiny beads of super glue catalyzed with sanding. More substantial chafing, thinning, or cracking should be repaired with filler. Submit photos in the evaluation for our professional assessment and tailored instructions.

Need to fix boat upholstery. Can I use a new piece of marine vinyl from a fabric shop as a graining paper?

Your idea is a good one, but you want a negative, not a positive, to emboss. Also, the graining pad is used just as the filler has been heat cured. Doing so when it’s still uncured and goopy will just make a mess of things. This is why, if using an air-dry filler, we complete the repair with a final thin coat and emboss it with a gloved hand while still wet.